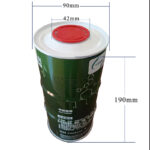

| Material | Prime tinplate |

| Capacity | 4 Liter |

| Thickness (mm) | 0.28mm or According to customers' requirements |

| Size (mm) | 168 (L) x 105 (W) x 260(H) mm, 180 (L) x 105 (W) x 240(H) mm or make a new mold |

| Outside | CMYK printing |

| Inside | Lacquered with 100% Phenolic epoxy resin |

| Certificate | MSDS, ISO 9001, UN approved |

| Sample | 2pcs are free of charge, customers just need to pay for the freight |

| Customization | 1) sample can for us to copy 2) layout or 3D drawing of the tin can or design 3) the size of the tin can |

| Payment | 30% T/T deposit in advance and 70% before shipment or Negotiated Method |

| Delivery time | General 15-25 days after payment and sample confirmed |

| Quality Control | With auto leakage testing machine, leakage rate is 3‰ in general. (we will try our best to be 1‰) If exceed this and our responsibility, we will make the best compensation solution. |

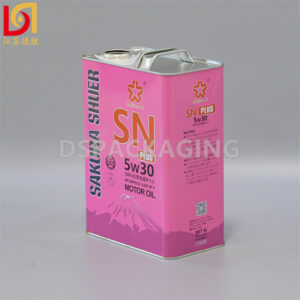

The benefits of F type cans manufactured by DS Packaging are obvious:

- It is usually used to fill engine oil, lubricating oil, brake oil, etc.

- The cans are rectangular tin containers, which can be stored on pallets to the maximum extent, because they can be packed without gaps, and are convenient for loading and unloading.

- Because of its excellent sealing performance, it provides the best package for the preservation oil.

- Customizable appearance printing makes products stand out and difficult to imitate/

- Environmentally friendly metal packaging makes buyers more socially responsible and contributes greatly to the environment!

As for the tin cans themselves, there are many options for accessories: metal / plastic handles, metal / plastic caps, different sizes and colors, and there is always one for you!

Our Existing F-style / Rectangular Small Tins

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Packaging & Delivery

In order to ensure the transportation safety of your goods, we will provide you with professional, environmentally friendly, convenient and efficient packaging.

- Inner plastic bag + standard export5-layer corrugated carton

- Inner plastic bag + carton + pallet

- Shrink wrap, and then fixed by straps on the pallets